P1 Panasonic Battery Plant Team Commits to Success, Finding New Ways to Tackle Unfamiliar Challenges

“If we had a dollar for every time one of us has said ‘we’ve never done that before,’ we could all probably retire.”

This is how Operations Manager Chris Champagne sums up the P1 experience at the Panasonic Battery Plant (aka “Project Kansas”) in DeSoto, KS – the largest battery plant in the world, and the largest project ever done in Kansas.

They say fortune favors the prepared, and P1 tackled this project with grit, a relentless commitment to success, and, of course, the “expertise of many”.

The project started with Wing 1 in 2023. Although there were both pipe and plumbing scopes, the lion’s share of the work ended up being sheet metal. The scope included four different contract areas in the building, totaling approximately 89,000 linear feet of pipe and 1.5 million pounds of duct.

Pipefitter Foreman Will Wall explains how the Wing 1 scope changed from the initial request. “The original request was to complete the work in the corridor of Wing 1 which got our foot in the door at the $25 million dollar mark,” Will said.

“As the project evolved, P1 was awarded more scope which grew the contract amount to $90 million.”

That additional scope included the sheet metal work in the plant‚Äôs formation and packing areas and the ¡Ò¡´ ”∆µ piping throughout the corridor, top cap, formation and packing areas.

Wing 1 wrapped up in 2025, and P1 was awarded Wing 2. The Wing 2 scope was almost a reversal of Wing 1, with a predominantly pipe scope, and less sheet metal. It includes two different areas of the plant, with approximately 106,000 linear feet of pipe and 600,000 pounds of duct.

Wing 2 construction is projected to wrap up in early 2027.

Looking back, the sheer size of Wing 1 still amazes the team. Sheet Metal Foreman Dave Wright says there were an estimated 4,000 construction workers on site for the project.

“During that first six months, it was hard to even get our head around the scale of what we were doing,” Dave said.

“There were more general foremen and foremen than you can imagine to keep everyone organized,” he added.

“The amount of equipment being delivered each week was amazing. We were hanging 12’ x 12’ ductwork and working with 72” spiral, sometimes 50 or 60 feet in the air.”

Will says the team installed exceptionally large pipe racks, including 4” x 12” pipe x 40’ long racks, and Plumbing Foreman Nate Christensen developed and installed a unique 24” storm drain system – 75 feet in the air.

“The challenge of working with this scale of material, with that many people, that high in the air, was certainly a new one for P1,” Chris said.

“The building was so expansive and spread out. On a typical job, one foreman might have a crew of about eight. On this one, it was more like four.”

The team noted that even keeping track of rentals alone was difficult, and P1 had to put tracking devices on no less than 115 scissor lifts.

Dave says he had approximately 100 sheet metal workers on site, and 15 at the special assembly shop.

“That’s four times more than I’ve ever had on one project,” he said.

In fact, this was the first job to implement the special assembly shop set up within P1’s Lawrence off-site construction facility. The shop space was developed specifically to assemble the massive ductwork for this project.

Above, left: P1 transported massive ductwork to the site. Right: lifting large pipe into the facility

The sheet metal work on this project doubled sheet metal shop production from around two million pounds in 2023 to four million pounds in 2024.

A lift-watch system was also new to P1.

“With the height and size we were dealing with, every crew had to have a dedicated person to watch lifts, ensuring coordination and safety,” Chris said.

The team agrees that two of the best takeaways from this project were preparation for future projects of this magnitude, and using P1’s “single source” capabilities to drive efficiency.

“There is a big difference between how we thought we would hang material before working on this job, and how we actually do it now,” Dave noted.

Dave says that in the beginning, P1 needed to look at how the other mechanical contractors on site were doing things, but by the end of the project, that changed.

“After P1 figured out solutions to a lot of these new challenges, we found that other subcontractors now look to us to see how we do it!”

Pipefitter Foreman Brooks Peek says the innovations the P1 team came up with for things P1 has never done before have primed P1 for more jobs like it.

“This job has allowed us to try things that are out of our comfort zone,” Brooks said. “The innovations we’ve applied have prepared us for similar jobs in the future.”

Brooks also notes that P1’s “single source” resources create a sounding board for the team.

“There are times when I don’t have the answer, but I can go talk to someone else from P1 who can help me see the issue differently – we are a team with multiple teams,” he said.

“Our trades aren’t siloed, there are no boundaries – we do a great job of working together.”

“In my entire career, I’ve never used our Millwrights as much as I have out here on all the racks the ductwork comes out on and the towers,” Dave added, “If we hadn’t had their capabilities in-house it would have made things far more difficult.”

Brooks also says having access to leadership on-site – because the project demands it – has made a big difference.

“Having project leadership right on site is so beneficial,” he said. “Impromptu meetings to address issues that arise can be pulled together, and decisions can be made quickly.”

Even though the project scope is mechanical, electrical scope gaps developed and the GC asked if P1’s electrical team could get involved.

Due to prior commitments, they were not able, but the team reached out to sister company P1 Service, who provided four Service electricians on site to help fill those gaps.

Take the example of Sheet Metal Foreman Kevin Warnecke. Kevin was working on sheet metal installation as would be expected, but now he’s also managing Test and Balance (TAB) for the project.

The GC asked P1 to help manage TAB, so P1 found a way.

“In addition to his sheet metal responsibilities, Kevin jumped in to manage the TAB contractor, and we’ve gotten great response on how helpful he’s been,” Chris said.

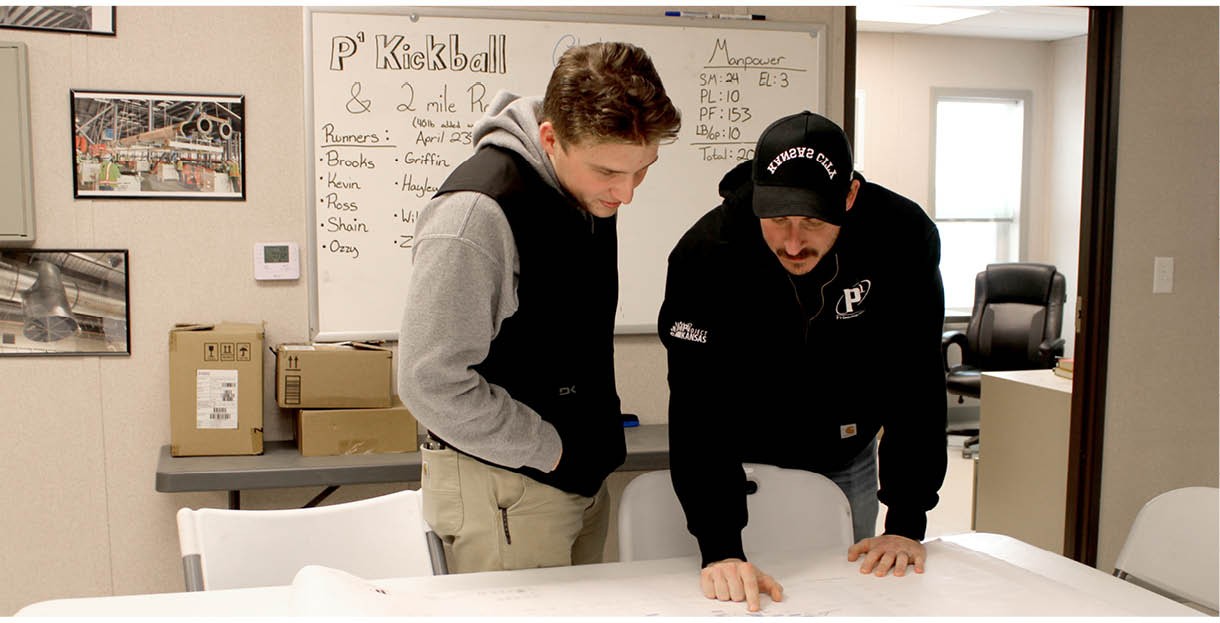

Project Engineer Griffin Souder and Sheet Metal Foreman Kevin Warnecke: Reading project plans or planning the next kickball game?

Project Engineer Griffin Souder and Sheet Metal Foreman Kevin Warnecke: Reading project plans or planning the next kickball game?

“We try to make ourselves the easy button – because we have those capabilities – and the GC appreciates that,” Chris said.

Plumbing Foreman Nate Christensen praises the team’s ability to meet deadlines.

“There wasn’t a single time a deadline wasn’t met because of P1,” Nate said.

“P1’s expertise drove the schedule in many meetings. We came in with our plan and the GC used our plan to build their schedules.”

Nate also notes that this experience led to more partnerships – even with competitors.

“The sheer amount of tie-ins on this project that required working hand-in-hand with other contractors was unusual,” he said.

“We talked to the other contractors on a daily basis on tie-in* points – there were hundreds on this project,” Nate said. “P1 was responsible for bringing our systems to a mutually agreed upon connection point, and then they tied in to us.”

“After awhile, you form partnerships, and get better at working together, rather than seeing each other as competition, at least for that project!”

*In construction, a "tie-in" refers to the crucial process of connecting two separate components or systems, like joining new piping to an existing line, linking building sections (walls, roofs), or creating seamless transitions for air/water barriers, ensuring overall system continuity and integrity.

Chris also points out that P1’s agility and innovation to quickly solve and execute on this job has built a trusted partnership with our customer, Southland.

“On Wing 1, Southland had four or five contractors, on Wing 2, it’s been scaled back to just P1 and one other contractor,” Chris said.

Southland has even asked P1 to look at other projects across the country.

“P1’s ability to pivot, adapt, and innovate drives a lot of the success at Project Kansas,” Chris said. “The field staff came up with the ideas we needed for how to hang duct and install equipment.”

Of course, internal organization is key, and that’s where Onsite Project Coordinator Jennifer Blomendahl comes in.

Affectionately dubbed “trailer mom,” Jennifer actually has the very challenging job of organizing and managing day-to-day activities from payroll to safety to managing new hires.

“I don’t know if I could do it if it weren’t for the great family atmosphere here. I felt welcome from the beginning,” Jennifer said. “The kind of support I’ve received from this team – and the company – makes even the most difficult days doable.”

Project Engineer Hayley Leonard has been an integral part of the Project Kansas team, from project organization to using her project knowledge to provide many tours of the Panasonic facility for P1 leadership and associates.

Hayley also started as a P1 intern several years ago and quickly moved up to Project Engineer. She says the camaraderie among the P1 team at Panasonic has been somewhat unique – and definitely keeps things fun.

“We have plenty of events that keep this team together,” she said.

“From our bigger events like pickleball and softball to smaller activities like putting a team together to support Zach [Kittle’s] Irish road bowling, and hosting pot luck lunches in the trailer. We try to balance the hard work with fun and a good sense of humor!”

For VDC Specialist Ozzy Scoggin - the “newest-to-P1” team member - being thrown into the fire of Project Kansas has its benefits.

A former P1 intern, Ozzy has worked on the project in a detailing role.

“This is my first project as a full-time associate at P1, and that sets the bar high for learning,” he said.

“I hope that working through such a big project right off the bat will make subsequent projects a little easier!”

At the end of the day, the entire team shares one thing in common: a relentless desire to succeed.

“Not one of us is willing to let the team down,” Jennifer said.

There’s a definite pride that comes with being able to say “we’re building something no one’s ever built before” and Project Kansas is proof that P1 is primed for the large, collaborative projects our industry demands today - and in the future.

LEADING THE WAY IN SAFETY

Chris notes that P1 exemplified our usual high level of safety standards during this project.

“An incident on this job is not like an incident on any other job, and if you don’t report it, you’re in trouble,”

he said.

“P1 had the most incidents reported of any contractor – not because we were having more problems, but because we are actually doing what we’re supposed to and following safety protocol.”

P1 even started a “Safety Rodeo” between projects – prior to Wing 1 and prior to Wing 2. The Safety Rodeo brings in vendors and suppliers, and workers spend the day at different stations going over critical safety items. These include things like how to do a lift watch, proper tie-offs*, and reviewing how to tether tools for working at great heights.

*“Tying off” in construction means connecting a worker's fall protection harness to a secure anchor point (like a beam or lifeline) to prevent falls - a critical safety practice.

The two-day helicopter lift required a 60-person team, with 40 on the roof and 20 on the ground. P1’s organization and precision even impressed the pilot!

The two-day helicopter lift required a 60-person team, with 40 on the roof and 20 on the ground. P1’s organization and precision even impressed the pilot!

A HELICOPTER PICK LIKE NO OTHER

“Pit crews” on a pick? In a way, yes! The team agrees the helicopter pick for this job was one of a kind and probably the most challenging in P1’s history.

There were 100 pieces of equipment, some 12 ft. tall, the heaviest at just under 13,000 lbs. – and all of it placed in just two days.

It was so complex it took six months of planning with plenty of new twists and turns along the way.

“Turner-Yates required 100% tie-off before the helicopter set equipment,” Chris said.

“This is something we never do because it can mean a worker can’t get away from an anchor point if something should go wrong.”

Remember, tying off means connecting a worker's fall protection harness to a secure anchor point. “100% tie-off," means continuous connection when exposed to fall hazards.

P1 was up to the task with our 60 person team – 40 on the roof, and 20 on the ground.

“We had to come up with a system, which entailed using something similar to pit crews for different tasks, each identified with different color vests,” Dave said.

The pilot even commented on how well-coordinated P1 was.

“They noted they couldn’t believe how we did the process the same every time,” Dave added. “He said he’d never seen something work like that – ever.”

P1’s Virtual Design & Construction experts also played an important role, laying out all the parts and pieces ahead of time.

Brooks notes there were some hiccups, but P1 was ready for it.

“P1 was so prepared that it all got done and those issues seem minimal now,” Brooks said. “We really demonstrated we could pivot repeatedly.”

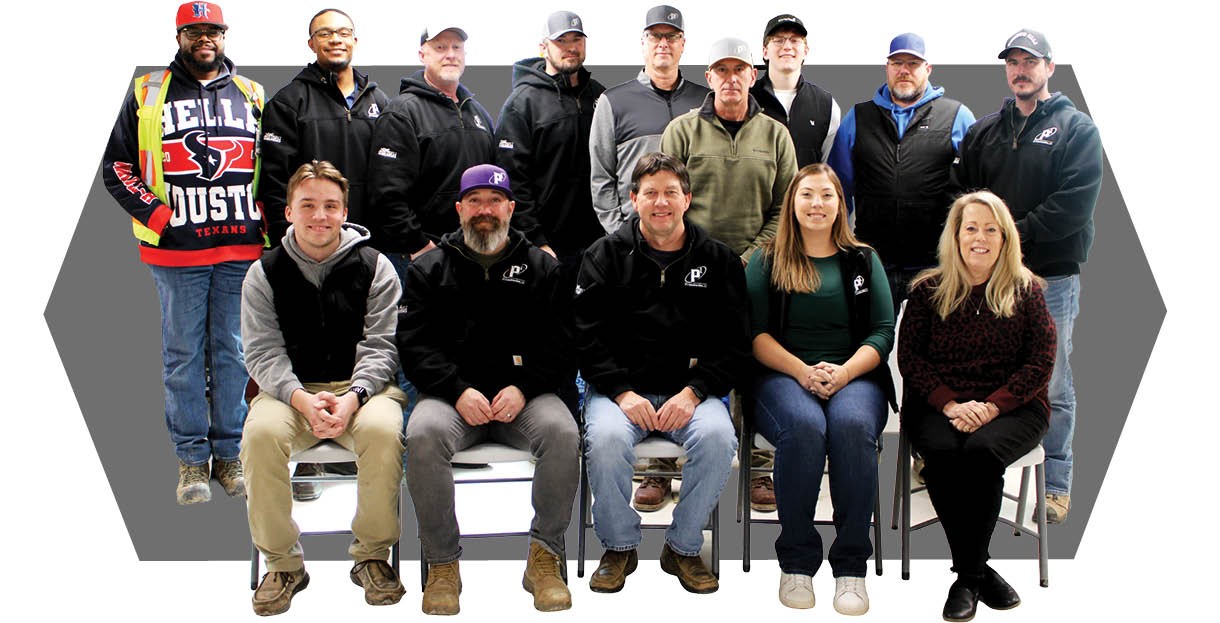

Pictured above, seated, from left: Griffin Souder, Zach Kittle, Chris Champagne, Hayley Leonard, Jennifer Blomendahl Standing, from left: Renauldo Hughes, Ross Williams, Nate Christensen, Brooks Peek, Dave Wright, Will Wall, Ozzy Scoggin, Steve Turner, Kevin Warnecke

Pictured above, seated, from left: Griffin Souder, Zach Kittle, Chris Champagne, Hayley Leonard, Jennifer Blomendahl Standing, from left: Renauldo Hughes, Ross Williams, Nate Christensen, Brooks Peek, Dave Wright, Will Wall, Ozzy Scoggin, Steve Turner, Kevin Warnecke

THE VILLAGE IT TAKES

With a project of this scope, the number of staff can become like its own company within P1, just dedicated to the job at hand. Here is a snapshot of the many people who contribute to the team effort at Project Kansas.

Leadership:

Vice President Glenn Shain (retired)

Vice President Eric Affolter

Team Lead: Operations Manager Chris Champagne

Safety: Renauldo Hughes, Jessica Sargent, Samuel Newton, August Lafauci, Don Campbell, Greg Sweeney, Bry Grame

Project Managers: Zachary Kittle, Nathan Pierce

General Superintendent: Will Wall

Field Supers/General Foreman: Dave Wright, Sheet Metal Superintendent; Steve Turner, Sheet Metal General Foreman; Nate Christensen, Plumbing Superintendent; Brooks Peek, Pipefitter Superintendent; Jordan King, Wing 2 Pipefitting General Foreman; Rick Adams, Wing 2 Pipefitting General Foreman; Tracy Johnson, QA/QC; Kevin Warnecke, TAB Lead

Virtual Design & Construction Team: Bret Faris, Andy Alderson, Brandon Ruud, Chris Wittman, Gary Kluender, Nathan Littlejohn, Richard Anderson, Steve Farve, Taylor Steel, Ozzy Scoggin

Estimating/Preconstruction Team: Dan Tylski, Amelia Mullin, Garrett Parker, Zack Provost

Cost Management: Nick Lawless, Tammi Kent

Project Engineers and Interns: Hayley Leonard, Ross Williams, Griffin Souder (former intern), Spencer Straub (returning intern)

Fabrication: Tom Keating (sheet metal); Jeremy Price (pipe/plumbing), Zach Noll (plumbing), Donnie Miller, Terra Jones, Carson Christian

Total Station: Michael Warner

P1 Service: Stephan Caine (Startup Technician); P1 Service Electrical Team: Alex Van Leeuwen, Project Manager; Field: Peter Vu, Chris Laycook, Raymond Neidholdt, Keith Everhart

P1 Construction Technologies: Michael Green

Project Coordination/ Support/Training: Sarah Garcia, Tennille Tegeler, Jennifer Blomendahl, Vicki Jesse

PJK QUICK FACTS

- Wing 1 Scope included four different contract areas in the building, totaling approximately 89,000 linear feet of pipe and 1.5 million lbs. of duct.

- The $25M scope evolved into a total of $90M as more was added, mostly sheet metal work.

- Wing 1 wrapped up in 2025, and P1 was awarded Wing 2, with a predominantly pipe scope including around 106,000 lf of pipe and 600,000 lbs. of duct.

- 12’ x 12’ ductwork and 72” spiral, sometimes 50 or 60 feet in the air.

- Exceptionally large pipe racks, including 4” x 12” pipe x 40’ long racks

- Unique 24” storm drain system 75 feet in the air

- 115 scissor lifts

- 100 sheet metal workers on site, and 15 at the special assembly shop

- Special assembly shop set up within P1’s Lawrence off-site construction facility specifically to assemble the massive ductwork for this project.

- The sheet metal work on this project doubled sheet metal shop production from around two million pounds in 2023 to four million pounds in 2024.

- Two-day helicopter pick with 100 pieces of equipment, some 12 ft. tall, the heaviest at just under 13,000 lbs.

- The pick required a 60-person team – 40 on the roof, and 20 on the ground.

¡Ò¡´ ”∆µ the author

P1 Construction is a single-source specialty subcontractor specializing in mechanical, electrical, millwright, and architectural metal construction facility solutions.